Home » Aerosol Fire Suppression System

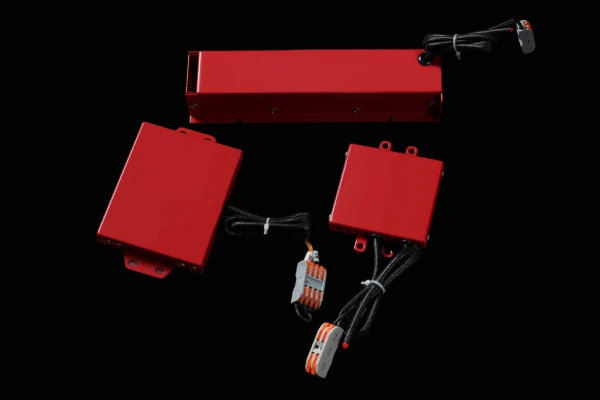

Aerosol Fire Suppression System

Aerosol fire suppression systems provide fast, efficient, and residue-free fire protection, making them ideal for small and confined spaces where traditional dry chemical suppression systems may not be suitable. These aerosol based fire suppression systems use a solid-state extinguishing agent, which decomposes upon activation, releasing ultra-fine extinguishing aerosols that chemically and physically disrupt the fire tetrahedron, breaking the chain reaction and absorbing heat to prevent re-ignition.

Unlike traditional extinguishing systems, aerosol fire extinguishing systems do not require pressurized storage tanks and are highly effective in special hazard environments. Certified by ATEX and UL, these aerosol fire systems offer easy to install options with control panel integration for automated or manual activation via fire alarm systems.

With compact dimensions (ø168×210 mm) and minimal maintenance requirements, aerosol fire extinguishers provide reliable fire protection in energy storage, industrial machinery, and other special hazard areas, ensuring compliance with global safety standards while delivering effective fire suppression in critical applications.

Key Features of Aerosol Fire Suppression Systems

- Compact & Space-Saving Design: Engineered for small enclosures, with ø168×210 mm dimensions, allowing installation in server rooms, machinery compartments, and telecom facilities.

- Fast & Effective Suppression: Deploys within ≤30 seconds, effectively extinguishing the fire in Class A, B, C, and E fires, ensuring minimal downtime and maximum asset protection.

- Residue-Free & Equipment-Safe: Leaves minimal solid particles upon evaporation, making it safe for electronics, industrial control panels, and precision equipment.

- No Pressurized Cylinders: Unlike clean agent or dry chemical systems, aerosol fire suppression systems do not require pressurized storage tanks, allowing greater installation flexibility and system scalability.

- Long Service Life & Low Maintenance: Operates for 10+ years, with DIY easy installation and minimal maintenance requirements, reducing total cost of ownership.

- Multiple Activation Methods: Supports electrical (DC3~24V / AC3-220V), thermal cord, and glass bulb activation via control panels and fire alarms for automated or manual response.

- Certified for Safety & Compliance: Meets ATEX, UL, NFPA 2010, and other international fire protection standards.

- Advanced Aerosol Generation: Uses aerosol generation technology to ensure rapid dispersion of extinguishing aerosols in confined spaces, optimizing suppression efficiency.

Aerosol vs. Clean Agent vs. Dry Chemical Suppression

Selecting the right fire suppression system depends on application needs, equipment sensitivity, environmental considerations, and regulatory compliance. Aerosol fire suppression systems provide compact, residue-minimal, and cost-effective protection for confined spaces. Clean agent systems offer zero-residue, environmentally friendly solutions, ideal for data centers and sensitive electronics. Dry chemical suppression, while effective for industrial hazards and fuel fires, leaves corrosive residue requiring extensive cleanup. The table below highlights key differences to help buyers determine the best fit for their fire protection needs.

| Feature | Aerosol Fire Suppression System | Clean Agent Fire Suppression | Dry Chemical Suppression |

| Residue & Cleanup | Minimal solid particles; does not damage electronics | No residue; safe for electronics | Leaves corrosive powder; requires extensive cleanup |

| Suppression Speed | ≤30 seconds | <10 seconds | Slower reaction time |

| Fire Suppression Type | Class A, B, C, E | Class A, B, C | Class A, B, C, D |

| System Size | Compact, space-efficient (ø168×210 mm) | Requires pressurized storage tanks | Large-scale deployment needed |

| Re-ignition Prevention | High; absorbs heat from fire zone | High; displaces oxygen completely | Moderate; limited re-ignition control |

| Environmental Impact | Low toxicity; minimal aerosol generation | Environmentally friendly; zero ozone depletion | Airborne contamination risk |

| Compliance & Certification | ATEX, UL, NFPA 2010 | NFPA 2001, UL 2166, FM Global | NFPA 17, NFPA 33 |

| Activation Method | Electrical/Thermal Cord/Glass Bulb | Electrical/Manual | Mechanical |

| Operation (Discharge) Time | ≤19 seconds | Varies by agent | Varies |

| Installation Flexibility | Compact, easy retrofit | Requires extensive piping | Requires rigid pipe systems |

| Use Life | 10+ years | 10-20 years | 5-10 years |

| Temperature Range | -40°C to +108°C | -40°C to +60°C | -20°C to +80°C |

Aerosol vs. Clean Agent vs. Dry Chemical Suppression

Data Centers & Telecom Infrastructure

- Protects server racks, telecom switches, network cabinets, and ATMs.

- Fits into confined spaces where clean agent or dry chemical systems are impractical.

- Electrically non-conductive, preventing damage to critical IT infrastructure.

Industrial Machinery & Manufacturing Facilities

- Ideal for robotic arms, CNC machines, and electrical control panels, where traditional extinguishing systems cannot be installed.

- Provides localized suppression to extinguish the fire before it spreads.

Electric Vehicles & Transportation

- Used in EV battery compartments, aircraft compartments, and marine vessels.

- Compact and reliable for high-risk mobile applications.

Energy Storage & Power Facilities

- Applied in electrical substations, energy storage units, renewable energy infrastructure.

- Protects mission-critical components from fire damage with minimal installation space.

Get in touch with us

FlareNix offers you customized fire protection services. If you are in need of fire protection services, please contact our professionals!

Our customer support service is the best in the industry, with a 100% customer satisfaction rating.

- Free Quote.

- One-Stop Service.

- 100% Satisfaction guarantee.

- Quality Certification.

- Free installation quotation.

- Free maintenance quotation.

- Free design of customized systems.

- Free remote services.

And more!!!