Home » Detection Tube Fire Suppression Systems

Fire Detection Tubing System

Intelligent, Self-Contained, and Cost-Effective Fire Suppression

The Fire Detection Tubing System is a self-contained, automatic fire suppression system designed for high-risk, enclosed environments where traditional fire suppression systems are impractical. Unlike conventional systems, fire detection tube requires no electrical power, external smoke detectors, or complex piping networks. Instead, fire detection tube uses a high-pressure fire detection tube, which automatically detects temperature increases and ruptures upon direct heat exposure (248°F – 356°F / 120°C – 180°C), instantly releasing the extinguishing agent and suppressing the fire.

According to FM Global reports, localized suppression systems like Fire Detection Tubing Systems reduce fire damage by up to 70% compared to traditional fire suppression systems in enclosed environments.

Certified to NFPA 17, NFPA 2001, UL 2166, FM Global, and OSHA 1910.157, this automatically detected system supports multiple fire extinguishing agents, including CO₂, FM-200, Novec 1230, and dry chemical powder, ensuring safe and effective protection for critical assets in industrial, transportation, and data center applications.

Types of Fire Detection Tubing System

Detection Tube

- Activation Temperature: 140℃ ± 10℃

- Service Life: 5-10 years

- Pressure Resistance: Up to 140 Bar

- Compatibility: Various extinguishing agents

CO2

Design Pressure: 12.4 MPa

Working Pressure: 5.7 MPa

Discharge Time: ≤60s

Container Volume: 70L

FM200

Extinguishing Agent: FM200 (HFC-227ea)

Activation Method: Thermal self-activation

Application: Equipment & asset protection

Compliance: NFPA 2001, UL 2166

Key Features

| Parameter | Value |

| Detection Tube Material | High-pressure, flexible polymer tubing |

| Activation Temperature | 248°F – 356°F (120°C – 180°C) |

| Operating Pressure | 290 – 500 psi (20 – 35 bar) |

| Suppression Agent Options | CO₂, FM-200, Novec 1230, dry chemical powder |

| Discharge Time | ≤10 seconds |

| Protection Coverage | 0.5m³ – 2m³ (Localized Suppression) |

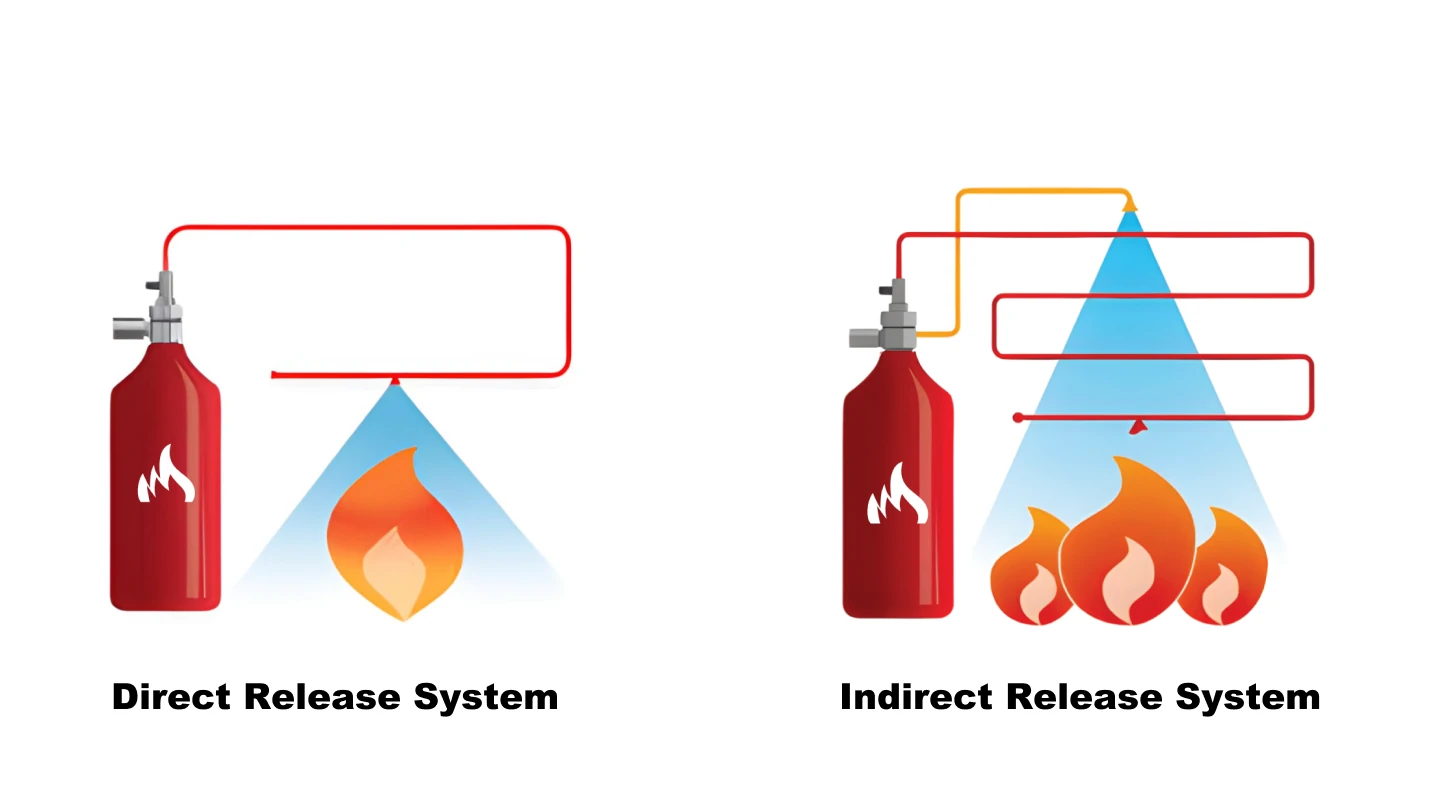

| System Type | Direct & Indirect Release |

| Installation Time | ≤2 hours (No external piping or power required) |

| Lifespan | 10+ years |

| Certification | NFPA 17, NFPA 2001, UL 2166, FM Global, OSHA 1910.157 |

Instant Heat-Activated Suppression – The high-pressure fire detection tube (290 – 500 psi / 20 – 35 bar) automatically detects fires and ruptures instantly when the temperature reaches 248°F – 356°F (120°C – 180°C), ensuring localized suppression at the ignition source within ≤10 seconds.

✔ No Electrical Power Required – Operates independently, eliminating power failure risks in industrial machinery, electrical cabinets, and vehicles.

✔ Multiple Suppression Agents Available – Compatible with CO₂, FM-200, Novec 1230, and dry chemical powders, allowing customized protection for different fire risks.

✔ Direct & Indirect Release Options – Supports localized suppression (direct release) or total flooding (indirect release), covering areas from 0.5m³ to 2m³.

✔ High-Pressure, Corrosion-Resistant Detection Tube – Withstands extreme vibrations, high temperatures, and exposure to industrial chemicals, ensuring long-term durability (10+ years lifespan).

✔ Minimal Maintenance & Low Cost – Requires only periodic pressure checks with no complicated installation or extensive maintenance requirements.

✔ OSHA & NFPA Compliance – Meets OSHA 1910.157 standards for CO₂ safety in enclosed areas and adheres to NFPA fire protection codes.

✔ Compact, Lightweight, and Easy to Install – Can be installed in under 2 hours without disrupting facility operations, making it ideal for retrofit applications.

Compared to conventional fire suppression systems, the Fire Detection Tubing System reduces installation costs by up to 40% and requires 50% less maintenance over a 10-year lifespan.

GET A QUOTE TODAY!

Protect critical assets with the Fire Detection Tubing System—instant activation, no power required, and NFPA-certified.

Applications & Industry-Specific Use Cases

Electrical & Server Cabinets

Protects high-voltage switchgear, data center server racks, and industrial control panels from fire hazards.

Non-conductive agents like FM-200 and Novec 1230 ensure safe suppression without damaging electronics.

Vehicles & Heavy Machinery

Installed in buses, mining trucks, forklifts, and automated vehicles to suppress engine and battery fires.

Meets FMVSS 302 and DOT safety standards for vehicle fire detection and suppression.

Industrial Equipment & CNC Machines

Provides localized fire extinguishing for robotic arms, CNC machines, and automated production lines, reducing downtime and equipment loss.

Supports dry chemical powder for quick fire suppression in manufacturing facilities.

Hazardous Material & Battery Storage

Used in lithium-ion battery enclosures, chemical storage rooms, and high-risk material compartments, ensuring instant suppression to prevent thermal runaway.

CO₂ and Novec 1230 are ideal for confined spaces where clean suppression is required.

Medical & Laboratory Equipment

Protects MRI machines, pharmaceutical storage units, and hazardous research facilities from fire hazards.

Maintains compliance with NFPA and healthcare safety standards.

Providing You with Outstanding Service

The Fire Detection Tubing System delivers fast, independent, and cost-effective fire suppression, making it the ideal choice for electrical panels, industrial machinery, transportation, and hazardous material storage. With instant activation, no power dependency, and flexible suppression agent compatibility, it ensures uninterrupted fire safety with minimal maintenance.

Certified to NFPA, UL, and FM Global standards, this system is trusted by industries worldwide for its high reliability, long lifespan, and ease of installation.

- Up to 40% lower installation costs compared to traditional fire suppression systems

- 50% lower maintenance costs over a 10-year lifespan

- Installation in under 2 hours—no downtime required

- NFPA, UL, and OSHA-compliant for industry-wide acceptance