Home » Dry Chemical Fire Suppression System

dry chemical fire suppression system

Fast-Acting Fire Protection for Industrial Applications

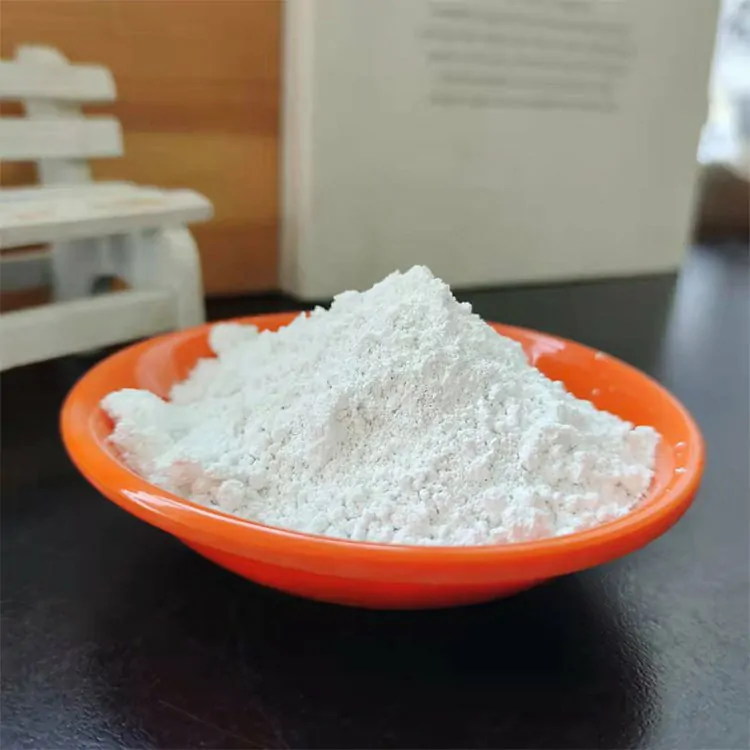

A dry chemical fire suppression system is a highly effective fire protection system designed for industrial applications where flammable liquid and fire hazards are major concerns. These dry chemical fire extinguishing systems use chemical agents to extinguish fires by disrupting the chemical chain reaction while smothering flames and preventing re-ignition.

Engineered for total flooding and localized suppression, dry chemical suppression systems are widely deployed in industrial settings, including paint booths, spray booths, power plants, and fuel storage facilities. Designed to comply with NFPA 17, NFPA 2001, UL 1254, and FM Global safety standards, these chemical fire suppression systems provide fast response, cost-effective operation, and high adaptability across various industries.

Types of FlareNix dry chemical fire suppression system

Types of Dry Chemical Fire Suppression Systems

Standard Dry Chemical Fire Suppression Systems

- Utilize sodium bicarbonate or monoammonium phosphate as chemical compounds, effective for Class B (flammable liquid) and Class C (electrical) fires.

- Best suited for localized applications such as fuel stations, paint booths, and chemical storage facilities.

- Integrated with sprinkler systems or piping systems for enhanced fire protection system coverage.

Ultra-Fine Dry Chemical Fire Suppression Systems

- Feature micronized dry chemical powder (~10µm in diameter), significantly increasing reactivity and suppression efficiency.

- Ideal for total flooding protection in data centers, electrical substations, and enclosed industrial environments.

- Extended suspension time (up to 30 minutes) prevents re-ignition in high-risk industrial settings.

🔹 Compliance & Certifications

All dry chemical fire suppression systems meet NFPA 17 (Dry Chemical Extinguishing Systems), NFPA 2001 (Hybrid Systems), UL 1254 (Extinguishing Units), and FM Global certification standards.

Get a quote today!

Protect your critical assets with a certified Dry Chemical Fire Suppression System—fast, reliable, and compliant.

Key Features of Dry Chemical Fire Suppression Systems

- Suppression Speed: Ultra-fine dry chemical suppression systems achieve full fire knockdown in less than 10 seconds.

- Operating Temperature Range: -40°F to 120°F (-40°C to 49°C) ensures reliability in harsh industrial applications.

- Storage & Discharge: Available in 20 lb (9 kg), 30 lb (14 kg), 60 lb (27 kg), and 125 lb (57 kg) capacities, allowing system activation through manual, automatic, or electric triggers.

- Discharge Mechanism: Utilizes corrosion-resistant nozzles, delivering uniform suppression through sprinkler system networks or standalone release units.

- System Activation: Features automatic detection with fire alarms and manual override, ensuring instant fire suppression in critical industrial settings.

- Environmental Impact: Unlike some chemical fire suppression systems, dry chemical suppression systems contain no halocarbons and do not contribute to ozone depletion.

Comparison: Dry Chemical vs. Clean Agent vs. Aerosol Suppression

Choosing the right fire suppression system depends on the application, fire class, and environmental impact. Dry chemical fire suppression systems offer cost-effective, high-speed fire control but leave some residue. Clean agent fire suppression systems provide residue-free, non-conductive protection for sensitive equipment. Aerosol fire suppression systems deliver compact, efficient suppression with minimal residue, making them ideal for confined spaces. Each fire suppression system has unique advantages, ensuring tailored fire protection for diverse industrial needs.

| Feature | Dry Chemical Fire Suppression System | Clean Agent Fire Suppression | Aerosol Fire Suppression |

| Fire Classes | A, B, C, E | A, B, C | A, B, C, E |

| Suppression Speed | <10 seconds | <10 seconds | Moderate (≤30 seconds) |

| Suppression Mechanism | Interrupts chemical chain reaction | Displaces oxygen & absorbs heat | Absorbs heat & disrupts fire |

| Residue & Cleanup | Powder residue (varies by agent) | No residue | Minimal residue |

| System Size | Scalable for industrial applications | Requires pressurized tanks | Compact, self-contained |

| Re-Ignition Prevention | Moderate | High | High |

| Environmental Impact | No ozone depletion, minimal particulates | Zero ozone depletion | Low toxicity |

| Compliance & Certification | NFPA 17, NFPA 2001, UL 1254, FM Global | NFPA 2001, UL 2166, FM Global | ATEX, UL |

| Ideal Applications | Fuel storage, spray booths, industrial sites | Data centers, telecom hubs | Energy storage, confined spaces |

Applications of Dry Chemical Fire Suppression Systems

Industrial & Manufacturing Facilities

- Protects assembly lines, CNC machines, and heavy equipment from fire hazards.

- Integrated into piping systems for spray booths and industrial settings.

Fuel Storage & Chemical Processing

- Designed for flammable liquid fire suppression in refineries, fuel stations, and hazardous chemical storage.

- Dry chemical powder-based systems provide quick discharge and localized suppression.

Power Plants & Electrical Infrastructure

- Prevents arc flash fires and protects high-voltage components in power substations.

- Ensures compliance with NFPA 70E and OSHA fire safety regulations.

Data Centers & High-Tech Facilities

- Offers total flooding suppression for server rooms and IT infrastructure.

- Provides non-conductive, high-speed extinguishing without damaging electrical components.

Automotive & Transportation Fire Protection

- Integrated into aircraft hangars, marine vessels, and mining vehicles.

- Meets FMVSS 302 and FAA suppression system requirements for transportation fire safety.

A dry chemical fire suppression system delivers high-speed, cost-effective fire suppression, making it a preferred choice for industrial applications where flammable liquid fire hazards pose a significant risk. Certified by NFPA 17, UL 1254, and FM Global, these systems offer scalable deployment, reliable system activation, and long-term compliance.

For paint booths, spray booths, fuel storage, and industrial settings, dry chemical fire extinguishing systems remain one of the most efficient, flexible, and widely used fire suppression solutions.

Providing You with Outstanding Service

FlareNix offers you customized fire protection services. If you are in need of fire protection services, please contact our professionals!

Our customer support service is the best in the industry, with a 100% customer satisfaction rating.

- Free Quote.

- One-Stop Service.

- 100% Satisfaction guarantee.

- Quality Certification.

- Free installation quotation.

- Free maintenance quotation.

- Free design of customized systems.

- Free remote services.

And more!!!