Home » Kitchen Fire Suppression

kitchen fire protection

Commercial kitchens pose a significant fire hazard in any industry, with cooking equipment responsible for 61% of all restaurant fires, according to the National Fire Protection Association (NFPA). These incidents can escalate rapidly, reaching temperatures of 1,000°F (537°C) within seconds, making immediate intervention essential to ensure effective fire safety.

To mitigate these dangers in what is considered a high risk environment, many commercial kitchens deploy kitchen fire suppression methods using wet chemical systems designed for Class K (grease and oil) fires. Unlike dry chemical systems or a fire extinguisher that may leave behind corrosive residue, these systems cool burning cooking oils while forming a protective foam layer that provides robust fire protection and prevents commercial kitchen fires. This approach is a prime example of commercial kitchen fire suppression.

For compact kitchens, food trucks, and mobile catering operations, fire suppression in kitchen environments is often achieved through an integrated commercial kitchen fire suppression system. This setup utilizes automatic fire detection tubing to quickly suppress kitchen fires and complies with NFPA 96, NFPA 17A, UL 300, and OSHA 1910.263, ensuring that commercial kitchen fire suppression measures meet U.S. safety regulations.

| Parameter | Specification |

| Fire Class | Class K (cooking oil & grease fires) |

| Suppression Agent | Potassium acetate-based wet chemical |

| Discharge Time | ≤10 seconds |

| Operating Pressure | 175 psi (12 bar) |

| Detection Temperature | 600–750°F (315–399°C) |

| Gas/Electric Shutoff | Automatic (activates within 3 seconds) |

| Foam Layer Thickness | 0.08–0.12 in (2–3 mm) |

| Certifications | NFPA 96, NFPA 17A, UL 300, ANSI / UL 1254 |

Fire Suppression in Kitchen Environments is Critical

The average kitchen fire spreads in less than 2 minutes, making a rapid and effective fire suppression solution absolutely critical for safety.

Rapid Activation – Our kitchen fire suppression systems activate within 10 seconds once temperatures exceed 750°F (399°C), preventing the rapid spread of kitchen fires.

Designed for Grease Fires – Wet chemical fire extinguishers neutralize cooking oils exceeding 680°F (360°C) and create a protective barrier to prevent re-ignition, ensuring effective fire suppression in kitchen scenarios.

Prevents Equipment Damage – Operating at 175 psi (12 bar), these systems ensure even distribution across every cooking area and protect essential cooking equipment from fire damage.

Automatic Gas & Power Shutoff – The system automatically disengages gas and electrical sources within 3 seconds, drastically reducing potential fire hazards.

Compliant with Industry Standards – Certified under NFPA 96, NFPA 17A, and UL 300, our solution meets stringent safety requirements used in commercial kitchen fire suppression. This technology is also a key component of restaurant fire suppression systems, and its versatility extends to mobile operations, making it ideal for food trucks.

Types of Commercial Kitchen Fire Suppression Systems

Wet Chemical Fire Suppression Systems

- The standard for restaurant fire suppression systems, providing quick extinguishing action for cooking oils and high-temperature fires.

- Discharges 1.5–2.5 gallons per minute (5.7–9.5 L/min), forming a 0.08–0.12 in (2–3 mm) protective foam layer.

- Certified by NFPA 96, NFPA 17A, UL 300, ensuring reliable fire protection in commercial kitchens.

Fire Detection Tubing Systems (For Mobile & Compact Kitchens)

- Uses a pressurized heat-sensitive detection tube rated for 400 psi (27 bar), bursting at 300°F (149°C) to deploy suppression agents.

- Ideal for food trucks, small kitchens, and high-risk mobile cooking areas.

- Automatically engages without requiring electricity, making it an efficient fire suppression system.

Alternative Systems

Why They Are Less Common in Kitchens

- Sprinkler systems: Effective for large facilities but inefficient for grease-based fires.

- Dry chemical suppression systems: Leave corrosive residue, requiring extensive cleaning before operations can resume.

- Aerosol fire suppression systems: Aerosol fire suppression systems work in confined spaces, but not ideal for high-temperature grease fires.

Applications of Kitchen Fire Suppression Systems

Restaurants & Cafeterias

Restaurants and cafeterias operate high-volume cooking equipment, increasing the risk of grease fires that can ignite at temperatures between 600–700°F (315–371°C). Open flames, deep fryers, and high-temperature griddles create an environment where fire can spread rapidly through accumulated grease in exhaust hoods and ductwork. A properly installed wet chemical fire suppression system, compliant with NFPA 96 and UL 300, automatically detects and suppresses fires within 10 seconds, cooling burning oils and forming a 0.08–0.12 in (2–3 mm) protective foam barrier to prevent reignition. Integrated gas and power shutoff mechanisms, activated within 3 seconds, further reduce the spread of fire and eliminate secondary ignition sources, ensuring business continuity while meeting fire code requirements. This approach is a proven method of kitchen fire suppression.

Hotel & Resort Kitchens

Luxury hotels and large resorts rely on round-the-clock kitchen operations to serve thousands of guests daily. These kitchens utilize multiple cooking stations, deep fryers, and grills, increasing grease accumulation in ventilation ducts that require suppression systems rated for 175 psi (12 bar) discharge pressure. Without proper fire suppression, a single kitchen fire can trigger hotel-wide evacuations and significant financial loss. A multi-zone wet chemical suppression system, designed for multi-hood configurations, provides even agent distribution at 1.5–2.5 gallons per minute (5.7–9.5 L/min), preventing extensive fire damage and maintaining uninterrupted kitchen operations. Compliance with NFPA 96 and OSHA 1910.263 ensures that hotels remain in adherence with strict fire safety regulations while minimizing insurance liabilities. Unlike sprinkler systems, this method prevents water damage and offers rapid response.

Hospital & Institutional Kitchens

In hospitals and assisted living facilities, kitchen operations must function continuously to provide meals to patients and staff. Given the vulnerability of these populations, fire safety is a primary concern, as smoke inhalation and fire-related evacuations can have life-threatening consequences. Institutional kitchens operate high-efficiency commercial appliances, including convection ovens, steam cookers, and fryers exceeding 700°F (371°C), making them susceptible to flash fires. Wet chemical fire suppression systems with manual pull stations placed within 25 feet (7.6 m) of all cooking appliances provide immediate fire suppression, preventing disruptions to food service. These systems automatically deactivate gas and electrical power within 3 seconds, stopping further fuel supply and ensuring compliance with NFPA 17A and UL 300 standards for commercial cooking operations. An advanced extinguishing system is often integrated to further enhance safety.

Food Trucks & Mobile Kitchens

The confined space of food trucks and mobile kitchens significantly increases fire hazards, as open flames, propane tanks, and electrical equipment are often positioned in close proximity. Additionally, mobile kitchens experience higher heat buildup, with ambient temperatures inside vehicles exceeding 120°F (49°C) on warm days, intensifying ignition risks. Fire detection tubing systems, operating under 400 psi (27 bar) pressure, provide a self-contained automatic suppression solution that detects heat and bursts when exposed to 300°F (149°C), releasing potassium acetate-based wet chemical agents directly onto ignition points. These compact suppression systems comply with NFPA 96 mobile kitchen requirements and prevent catastrophic fire damage in mobile food operations, ensuring vendors meet local fire department regulations. This is a prime example of fire suppression in kitchen environments adapted for mobile operations.

Industrial & Commercial Catering Facilities

High-capacity catering operations rely on multiple cooking zones, conveyor ovens, and deep fryers, creating a fire load that can exceed 1.5 MW per kitchen station. In large-scale food production, where uninterrupted operation is essential, the suppression solution must support multi-zone coverage with discharge rates of 7–10 gallons (26.5–38 L) per activation. Foam-forming suppression agents, applied at a velocity exceeding 30 ft/sec (9.1 m/sec), cool fire-prone surfaces while minimizing disruption to surrounding areas. Integrated with ventilation fire dampers to prevent flame spread through ductwork, these systems help catering businesses maintain compliance with NFPA 96 and NFPA 17A, ensuring operational safety and reducing downtime. Implementing a commercial kitchen fire suppression strategy is critical for such facilities.

These comprehensive measures provide restaurant operators with peace of mind knowing their operations are safeguarded.

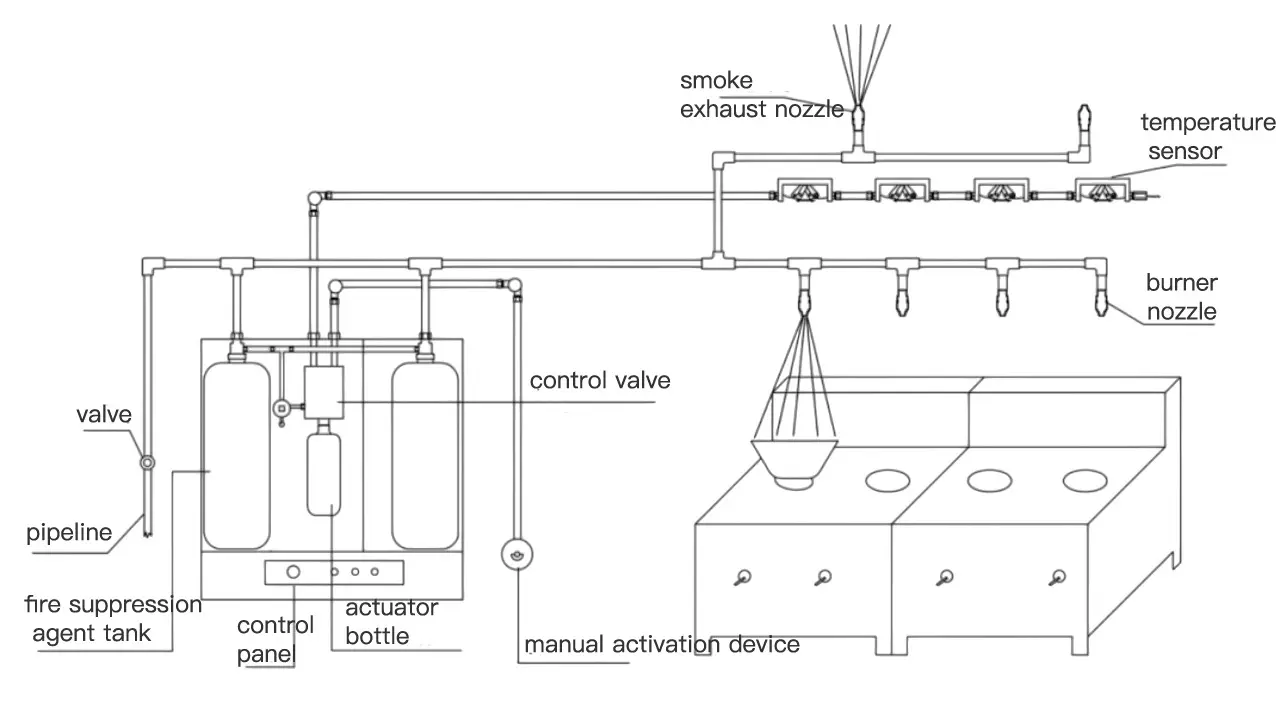

How a Kitchen Fire Suppression System Works

A kitchen fire suppression system is a specialized fire protection solution designed to automatically detect and extinguish fires before they escalate. In commercial kitchens, where cooking equipment, cooking oils, and high temperatures create a constant fire hazard, a properly installed fire suppression system works within seconds to control and eliminate fires while minimizing damage.

Fire Detection

A kitchen fire suppression system constantly monitors heat levels in the cooking area using thermal sensors, fusible links, or fire detection tubing. When temperatures exceed 600–750°F (315–399°C)—a critical point where cooking oils can self-ignite—the system automatically triggers. Unlike manual fire extinguishers, which require an operator, this automatic detection process ensures that fires are controlled instantly, even when staff is not present. Food trucks and compact kitchens may also utilize fire detection tubing, which bursts upon exposure to extreme heat, immediately engaging the suppression process.

Activation of Extinguishing System

Once a fire is detected, the fire suppression system works by instantly releasing wet chemical extinguishing agents through a network of nozzles positioned above cooking equipment. These restaurant fire suppression systems are designed specifically for commercial kitchens, where grease fires are common. The wet chemical reacts with cooking oils, causing saponification, a chemical reaction that rapidly cools the flames and forms a protective barrier to prevent re-ignition. This process occurs within 10 seconds, ensuring minimal fire spread while keeping cooking equipment and ventilation systems protected.

Automatic Gas and Power Shutoff

To eliminate fuel sources that could feed the fire, the kitchen fire suppression system integrates automatic gas and electrical shutoff mechanisms. Within 3 seconds of system activation, gas valves close, and electrical power to nearby cooking equipment is disengaged. This feature is crucial in high-risk commercial kitchens, preventing secondary ignition sources from reigniting flames. The shutoff function also complies with NFPA 96, UL 300, and OSHA fire safety standards, ensuring the highest level of fire protection in restaurants, hotels, and institutional kitchens.

Post-Fire Safety & Cleanup

After the fire has been extinguished, the system ensures that the affected area is safe before allowing kitchen staff to resume operations. The wet chemical extinguishing system leaves minimal residue, making it easy to clean without damaging cooking equipment. Unlike dry chemical fire suppression systems, which can be corrosive and require extensive cleaning, wet chemical systems allow for fast kitchen restoration, reducing downtime. Fire safety regulations require that, after activation, a certified technician inspects and recharges the system before it is reset for continued protection.

Get a free quote today!

Protect your kitchen with a reliable fire suppression system

✔ Automatically suppresses fires within 10 seconds, minimizing damage and ensuring business continuity.

✔ Designed for high-risk commercial kitchens, preventing the spread of grease and cooking oil fires.

✔ Complies with NFPA 96, UL 300, and OSHA safety standards, ensuring regulatory approval.

✔ Prevents fire re-ignition and allows for quick cleanup, ensuring peace of mind for business owners.

And more!!!