In today’s commercial landscape—where facilities are denser, operations run 24/7, and critical equipment is integrated into every function—the commercial fire risk profile has changed. According to the National Fire Protection Association (NFPA), U.S. fire departments respond to over 1.3 million fires annually, resulting in more than $15 billion in direct property loss. Notably, over 30% of these fires occur in non-residential structures, including office buildings, warehouses, retail spaces, and manufacturing facilities.

Unlike residential buildings, commercial environments concentrate high occupant loads, combustible contents, and vital infrastructure such as control panels and specialized machinery. This makes them not only more vulnerable to rapid fire development but also more reliant on uninterrupted operations. While fire protection systems—such as fire-rated assemblies and smoke compartments—remain foundational, they are not designed to suppress the fire or stop flame spread at its source.

As defined in NFPA 2001 and other applicable codes, a properly engineered fire suppression system provides an essential layer of protection by detecting, containing, and extinguishing fires within seconds. These systems include clean agents, sprinkler systems, foam systems, and dry chemicals, each selected based on the facility type, fire class, and operational environment. For safety officers, facility managers, and system designers, recognizing the limitations of passive barriers and adopting the right type of fire protection system is no longer just best practice—it’s a business-critical necessity for fire safety and safe evacuation.

Commercial Fire Suppression Systems

In commercial environments where seconds determine outcomes and asset loss can translate into millions in downtime, a fire is not simply a safety issue—it’s a business continuity threat. A clean agent fire suppression system is an engineered solution designed to detect and extinguish a fire automatically in high-risk operational settings, well before manual intervention or external response can occur.

Clean Agent

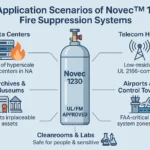

Commercial fire suppression system forms part of a facility’s critical fire protection infrastructure. A properly designed fire suppression system is not merely a passive safeguard, but an active, intelligent response mechanism that detects thermal, smoke, or flame signatures and deploys appropriate fire extinguishing systems within seconds. Clean agent fire suppressant technologies are ideal for occupied spaces, including data centers, commercial kitchens, and high-value manufacturing areas. Most clean agent fire suppression systems are built in accordance with NFPA 2001, NFPA 17, or UL 300, depending on the system type and suppression medium.

Difference

Unlike municipal or residential fire protection systems, which rely primarily on public sprinkler systems and manual firefighting response, commercial fire suppression systems are purpose-built to address complex and time-sensitive threats in modern facilities. Integration with fire alarms, smoke detectors, and building automation allows clean agent fire suppression systems to operate even during unstaffed hours. In addition to extinguishing a fire rapidly, many systems—such as FM-200 clean agent systems—are designed to leave no residue, protect sensitive equipment, and minimize the risk of water damage.

Types of Commercial Fire Suppression Systems

FM-200 fire suppression systems (NFPA 2001): A clean agent composed of carbon fluorine and hydrogen, electrically non-conductive, and fast-acting. FM-200 clean agent systems are ideal for mission-critical facilities where residue or moisture cannot be tolerated.

Sprinkler systems (NFPA 13): Traditional water-based fire extinguishing systems, widely used in retail spaces, warehouses, and general commercial buildings.

Foam systems (NFPA 11): Designed to suppress fires involving flammable liquids. Foam systems are common in fuel handling zones and chemical processing plants.

Dry chemical systems (NFPA 17, UL 300): Deployed in commercial kitchens, paint booths, and industrial machinery enclosures, where chemical agents are used to suppress fires immediately.

Hybrid systems: Combine multiple suppression media to address overlapping hazards and protect areas with varied fire risk classifications.

For facility managers, AHJs (Authorities Having Jurisdiction), and fire protection engineers, selecting the appropriate type of fire suppression system is not just about meeting code—it is about stopping ordinary combustible, electrical, and flammable liquid fires before they cause significant damage. A well-specified clean agent fire suppression system offers an extra margin of safety for people, equipment, and business continuity. Choosing the right system is no longer a precaution—it is a critical part of modern fire safety strategy.

Components

In commercial environments where fires can escalate within seconds and lead to severe financial and operational disruption, a properly designed and fully integrated clean agent fire suppression system is not a luxury—it is mission-critical infrastructure. A clean agent fire suppression system is engineered not only to detect fire hazards early but also to extinguish a fire within seconds, minimizing damage, protecting human life, and ensuring business continuity.

A complete clean agent fire suppression system includes three primary layers: the suppression agent, the hardware system, and the supporting infrastructure. All components must comply with current design standards issued by NFPA, UL, and the United States Environmental Protection regulatory framework, especially for systems utilizing clean agent fire suppressant technologies.

Suppression Agents

The suppression agent defines how effectively a fire is controlled and how well surrounding equipment and personnel are protected. Commercial facilities often choose from:

FM-200 fire suppression systems, composed of carbon fluorine and hydrogen, deliver rapid discharge, require limited storage space, and are safe for use in occupied spaces. FM-200 fire suppression systems are engineered to reach extinguishing levels in under 10 seconds, making them ideal for critical environments such as data centers, medical labs, and telecommunications facilities.

Inert gas systems (e.g., IG-100, IG-541) offer zero ozone depletion and zero global warming potential, although they require larger tanks and higher discharge pressures.

Foam systems and dry chemical agents are used in high-hazard zones such as fuel depots, spray booths, or commercial kitchens, where flammable liquids present a serious risk.

All suppression agents must be listed under the SNAP program maintained by the States Environmental Protection Agency, ensuring compliance with environmental and performance benchmarks.

System Hardware

Hardware is the central nervous system of every commercial fire suppression solution. Each component must operate in coordination to ensure complete system performance. Core hardware elements include:

Detection devices: These include heat sensors, aspirating smoke detectors, flame detectors, and air-sampling units. Devices must be tailored to the specific fire load and airflow characteristics of each commercial space.

Control panels: UL-listed, microprocessor-driven panels process detection input and initiate agent discharge, activate fire alarms, and send alerts to building systems. These panels are critical to precise, millisecond-level response and occupant notification.

Actuation and release mechanisms: Solenoid valves, pneumatic actuators, and pressure regulators—compliant with UL 864—are used to deploy the suppression agent. These components must be precisely timed with discharge logic to ensure full room saturation.

Discharge nozzles: Engineered for directional coverage and pressure balance, nozzles ensure agent dispersion across all threat areas. Incorrect nozzle placement can compromise performance or trigger turbulence in high-ceiling environments.

Experienced system integrators often use CAD-based flow simulations to validate nozzle placement and discharge velocity prior to final installation.

System Infrastructure

The supporting infrastructure ensures that every part of the commercial fire suppression system delivers performance under all conditions. Infrastructure elements include:

Agent cylinders: FM-200 fire suppression systems typically use cylinders ranging from 16 to 1,200 pounds, stored at approximately 360 psi. Cylinder sizing depends on enclosure volume, target concentration, and hold time requirements.

Piping networks: Stainless steel or Schedule 40 galvanized piping is used to transport suppression agents throughout the facility. All piping must meet relevant pressure and corrosion resistance ratings.

Wiring and power backup: UL-rated power circuits, battery backups, and relay modules ensure uninterrupted function during electrical failure scenarios.

Alarm and supervisory interfaces: These components connect the suppression system to the broader fire protection infrastructure, including fire extinguishing systems, fire alarms, smoke detectors, and safe evacuation notification systems. NFPA 72 compliance is required for system-wide signaling integrity.

Maintenance and inspection of all components—cylinders, valves, detectors, and wiring—must follow established procedures defined in NFPA 25 or NFPA 2001, depending on the suppression agent used. Neglecting routine service can compromise response times and system reliability.

Cost

The cost of a commercial fire suppression system for commercial use depends on the type of suppression agent selected, facility type, system complexity, and regulatory requirements. To accurately assess the investment, total cost must be evaluated from two perspectives: initial procurement and installation, and ongoing maintenance and lifecycle management. While upfront expenses may seem significant, the financial impact of insufficient fire protection—such as downtime, equipment loss, or compliance violations—can far exceed the initial investment.

Procurement and Installation Costs

Procurement and installation costs vary widely depending on the suppression agent used, the size and layout of the protected area, number of discharge zones, and integration with existing systems. Based on typical industry pricing and manufacturer quotes, here is a breakdown by application type:

| Facility Type | Recommended System Type | Estimated Cost | Notes |

| Data Centers / Control Rooms | FM-200 fire suppression systems | $25 – $45 / ft² | Includes fire extinguishing systems, control panel, nozzles, detection, piping, and labor |

| (a clean agent composed of carbon fluorine and hydrogen, electrically non conductive, and leaves no residue) | |||

| Commercial Kitchens | Wet or Dry Chemical Systems | $3,000 – $8,000 / hood | Based on hood size, duct layout, and exhaust system integration |

| UL 300 Compliant | |||

| Warehouses / Manufacturing | Foam Systems or Inert Gas Systems | $20 – $35 / ft² | Suitable for large open areas with flammable liquids; cost reflects piping and storage space for cylinders |

| Additional Cost Drivers | – Integration with fire alarms, smoke detectors, control panels | Varies | Requires custom engineering based on risk profile and local code requirements |

| – Ceiling height, zoning, special hazards | |||

| – Cylinder racking or ventilation modifications |

Maintenance and Lifecycle Costs

Maintenance is a critical part of any commercial fire protection strategy. According to NFPA 25, NFPA 72, and NFPA 2001, clean agent fire suppression systems require routine inspection and testing to remain compliant and reliable.

| Cost Item | Description | Typical Cost |

| Annual Inspections & Testing | Includes testing of detectors, pressure gauges, battery backups, nozzles, and agent levels | $500 – $1,500 / system / year |

| Compliant with NFPA 25, NFPA 72, and NFPA 2001 | ||

| Cylinder Recharge or Replacement | After system discharge, agent cylinders must be refilled or replaced | $300 – $1,200 / cylinder |

| FM-200 cylinders range from 16 to 1,200 lbs at ~360 psi | ||

| System Expansion / Retrofit | Required during facility upgrades or layout changes | Case by case |

| May involve nozzle additions, agent recalculations, pipe rerouting | ||

| Optional Enhancements | – Redundant detection circuits | Quoted separately |

| – Remote monitoring modules | ||

| – Simulated discharge testing (no agent release) |

A well-designed commercial fire suppression system is more than code compliance—it’s a strategic safeguard for people, assets, and uptime. When tailored to facility risks, the system extinguishes a fire early, minimizes damage, and delivers an extra margin of safety for people in occupied spaces.

Smart organizations evaluate fire protection with a Total Cost of Ownership mindset, considering long-term reliability, recharge costs, and system adaptability—not just the initial price.

Flarenix delivers custom-engineered, NFPA-compliant fire extinguishing systems for critical commercial environments. Speak with a Flarenix fire protection expert today to build a system that protects what matters—before disaster strikes.

Are you looking for a Commercial Fire Suppression System?

Please contact us immediately to arrange a free technical support consultation.