Home » IG-100 Nitrogen Fire Suppression System

IG-100 Fire Suppression System

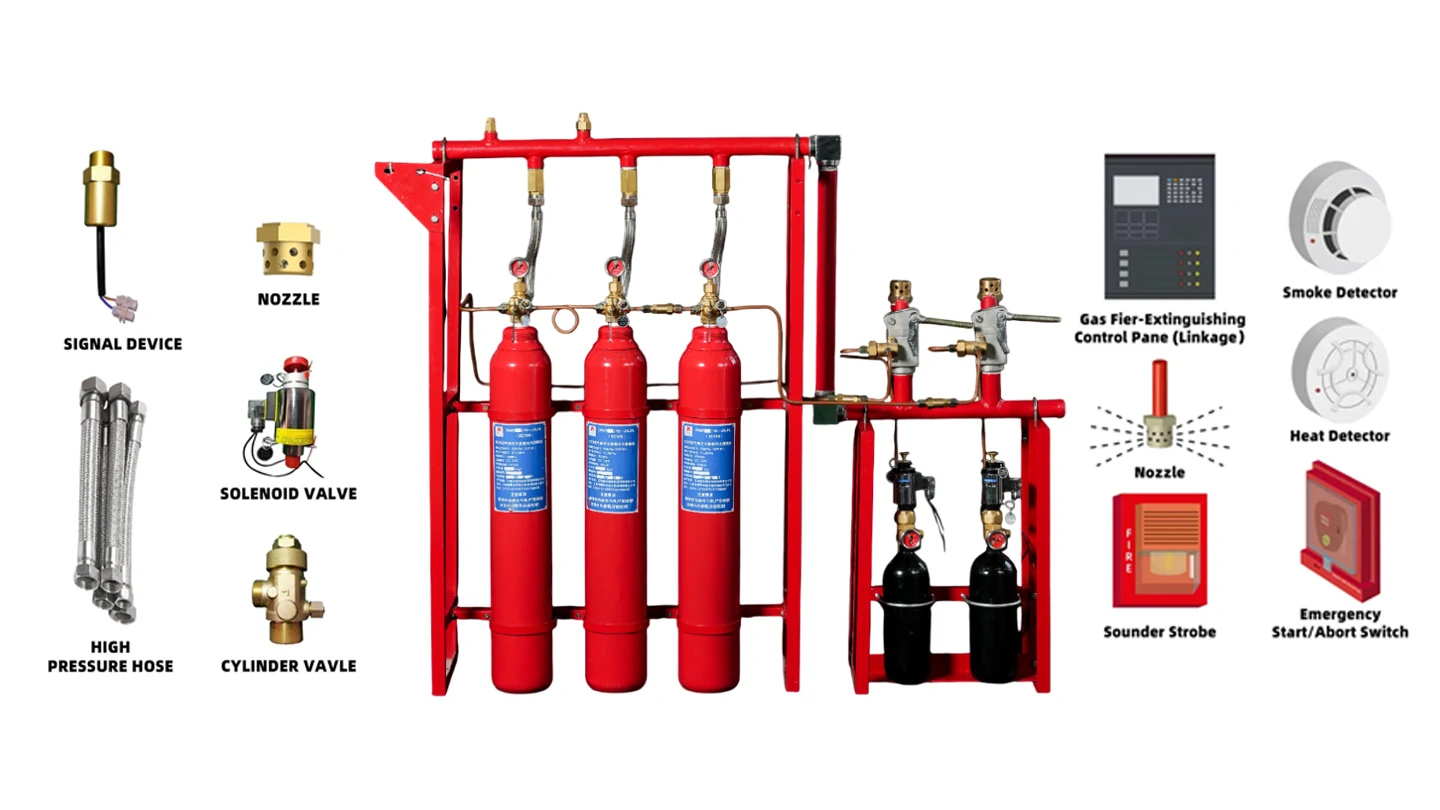

The Flarenix IG 100 fire suppression system is a clean agent fire suppression solution utilizing 100% pure nitrogen (IG 100) for safe, effective, and environmentally friendly fire suppression. As an inert gas system, the IG 100 fire suppression system is non-toxic, residue-free, and ideal for occupied spaces, making it a preferred choice for high-value asset protection in data centers, power facilities, and mission-critical environments.

This IG-100 system operates by reducing the oxygen concentration in the protected space to a level that prevents combustion while remaining safe for human occupancy. Unlike CO₂-based fire suppression systems, which require complete personnel evacuation, the IG 100 fire suppression system allows for continued operation in occupied environments. Additionally, compared to synthetic extinguishing systems like FM-200 and Novec 1230, IG 100 is naturally occurring, making it cost-effective and free from environmental restrictions.

With a working pressure of 300 bar, the system ensures consistent fire suppression across large enclosures. The Flarenix IG 100 fire suppression system meets NFPA 2001, UL, and FM global fire safety standards, ensuring high reliability and regulatory compliance.

Key Features

- 100% Pure Nitrogen Suppression – Environmentally friendly, non-toxic, and safe for occupied spaces.

- Extended Discharge & Multi-Zone Protection – The system’s high-pressure nitrogen storage (300 bar) allows for longer pipe runs, making it ideal for large or multi-room fire suppression applications.

- Uniform Fire Suppression Across Protected Spaces – Ensures quick nitrogen discharge, effectively reducing the oxygen concentration while suppressing fire and preventing fire spread.

- Non-Damaging & Residue-Free Fire Suppression – Protects sensitive equipment, electronics, and data centers without the risk of corrosion or contamination.

- Compliant with NFPA 2001 & UL Listed – Fully certified for global fire suppression systems and meets industry-specific safety regulations.

- Highly Configurable & Scalable – Can be integrated with fire detection systems, alarms, and gas release indicators, ensuring enhanced safety and operational flexibility.

- Lower Lifecycle Costs – Unlike synthetic extinguishing systems (FM-200, Novec 1230), IG 100 has no expiration date, requires no chemical refills, and reduces long-term maintenance costs.

- Optimized Design Concentrations – The system is engineered to meet NFPA 2001 design concentrations, ensuring maximum fire suppression efficiency.

Technical Specifications

| Technical Parameter | 80L Model (OMD15/80-FN) | 90L Model (QMD15/90-FN) | Imperial Units |

| Design Pressure | 300 bar | 300 bar | 4351 psi |

| Working Pressure | 15 MPa | 15 MPa | 2175 psi |

| Operating Temperature Range | 0°C to +50°C | 0°C to +50°C | 32°F to 122°F |

| Cylinder Volume | 80L | 90L | 21.1 gal / 23.8 gal |

| Cylinder Outer Diameter | Ø279 mm | Ø279 mm / Ø325 mm | Ø10.98 in / Ø12.80 in |

| Cylinder Height | 1578 ± 73 mm | 1345 ± 60 mm | 62.1 ± 2.87 in / 52.9 ± 2.36 in |

| IG 100 Gas Fill Weight | 14.25 kg | 16.04 kg | 31.4 lb / 35.4 lb |

| Cylinder Valve Nominal Size | DN15 | DN15 | 0.59 in (Nominal) |

| Cylinder Valve Outlet Thread | M30 × 1.5 | M30 × 1.5 | Metric |

| Safety Relief Pressure | 23 MPa ± 1.15 MPa | 23 MPa ± 1.15 MPa | 3335 psi ± 167 psi |

Application

The IG 100 fire suppression system is designed for high-value asset protection, ensuring clean, effective, and safe fire suppression in mission-critical environments.

Data Centers & IT Facilities

The IG 100 fire suppression system is the ideal fire suppression solution for sensitive electronics, providing residue-free protection for servers, network infrastructure, and storage arrays while ensuring no electrical interference.

Industrial & Power Generation Facilities

Protects transformers, control rooms, and generator enclosures, where fire suppression must be immediate and non-conductive. The high-pressure inert gas fire suppression system ensures uniform suppression without damaging critical infrastructure.

Telecommunications & Broadcast Centers

Ensures fire suppression systems for network switch rooms, signal relay points, and broadcast equipment, preventing data loss and service interruptions without harmful chemical residue.

Museums, Archives & Libraries

Provides fire suppression without water damage, ensuring valuable documents, historical artifacts, and sensitive materials remain intact.

Custom Solutions

The IG 100 fire suppression system is an advanced inert gas fire suppression solution, offering high-pressure, residue-free fire suppression for critical industries.

- 100% clean, safe, and environmentally friendly nitrogen suppression

- No chemical degradation, reducing long-term maintenance costs

- Meets NFPA 2001 standards and is UL Listed for compliance

- Ideal for occupied spaces, providing safe fire suppression

- Scalable system design, supporting multi-zone protection

Contact us today to integrate this high-performance IG 100 fire suppression system into your facility.