According to NFPA and FM Global data, fires in critical facilities such as server rooms, data centers, and power plants result in over $1.3 billion in losses annually, with traditional suppression methods often causing additional fire damage.

Clean agents offer a solution by providing electrically non-conductive, volatile or gaseous fire extinguishing for Class A, B, and C fires. Defined under NFPA 2001, these agents achieve total flood protection within 10 seconds, with design concentrations as low as 4.5% (FK-5-1-12) or 7.0% (HFC-227ea). Unlike water or dry chemicals that leave a residue, clean agents ensure rapid suppression without damaging sensitive assets.

Different clean agents function through varying mechanisms. Some, like Novec 1230, remove heat from the fire, while others, such as inert gases, reduce oxygen levels to suppress combustion. Their ability to extinguish fires effectively without secondary damage makes them essential for mission-critical environments.

With proven performance in UL 2127 and FM 5600 testing, clean agents are a key technology in modern fire protection. But what makes them effective, and how do they compare across different applications?

What is a clean agent

Clean agent fire suppressants are gaseous or volatile extinguishing agents that extinguish fires without conducting electricity or leaving corrosive residues. Clean agent are widely used in server rooms, control centers, and mission-critical facilities where traditional fire sprinkler systems can cause fire damage to sensitive equipment.

Clean agent fire suppression systems operate through two primary mechanisms: some, like Novec 1230 (C6F12O), use a high heat capacity (1.6 J/g·K) to absorb thermal energy, rapidly cooling the fire below its combustion threshold. Others, such as nitrogen, argon, and carbon dioxide, suppress flames by reducing oxygen concentration from 20.9% to 12-15%, a level that stops combustion but remains safe for human occupants.

Clean agent fire suppression systems are safe for occupied spaces and achieve total flood suppression within ≤10 seconds, meeting NFPA 2001 and ISO 14520 standards. Design concentrations vary based on the agent and fire class, with HFC-227ea requiring 7.0% concentration for Class A fires, while Novec 1230 is effective at just 4.2%. Unlike fire sprinkler systems, which can cause extensive water damage, clean agents fully evaporate after discharge, eliminating the risk of corrosive residues that require post-fire cleanup and ensuring minimal downtime for critical operations.

With regulatory approvals from EPA SNAP, UL 2127, and FM 5600, clean agents are an environmentally friendly solution in total flooding systems and portable extinguishers (UL 2166). Their rapid suppression capabilities, compliance with clean agent fire suppression standards, and ability to protect high-value assets with minimal downtime make them an industry-standard choice in fire protection.

Release Methods

Fire suppression using clean agent technology depends on the agent’s physical state, storage pressure, discharge characteristics, and fire suppression requirements. Unlike water-based fire sprinkler systems, clean agents provide electrically non-conductive, residue-free suppression that minimizes fire damage in critical environments such as server rooms, control centers, and high-value asset facilities. The primary deployment methods are portable extinguishers, total flooding systems, and specialized hybrid or aerosol-based suppression.

Clean Agent Fire Extinguishers

Portable clean agent fire extinguishers are effective for localized fire threats. Agents like HFC-227ea (-16.4°C boiling point, 450 kPa vapor pressure at 25°C) and FE-36 (-1.4°C, 213 kPa) vaporize instantly upon discharge, making them ideal for electronics and aviation. Novec 1230 (49°C, 0.4 kPa) requires high-pressure nozzles for rapid dispersion.

Applications:

- Electronics & Data Centers: Safe for server rooms and control panels.

- Aviation & Vehicles: Used in aircraft cargo holds and engine compartments.

- Medical Facilities & Labs: Provides clean suppression without contamination.

However, limited discharge volume makes extinguishers ineffective for large-scale fires.

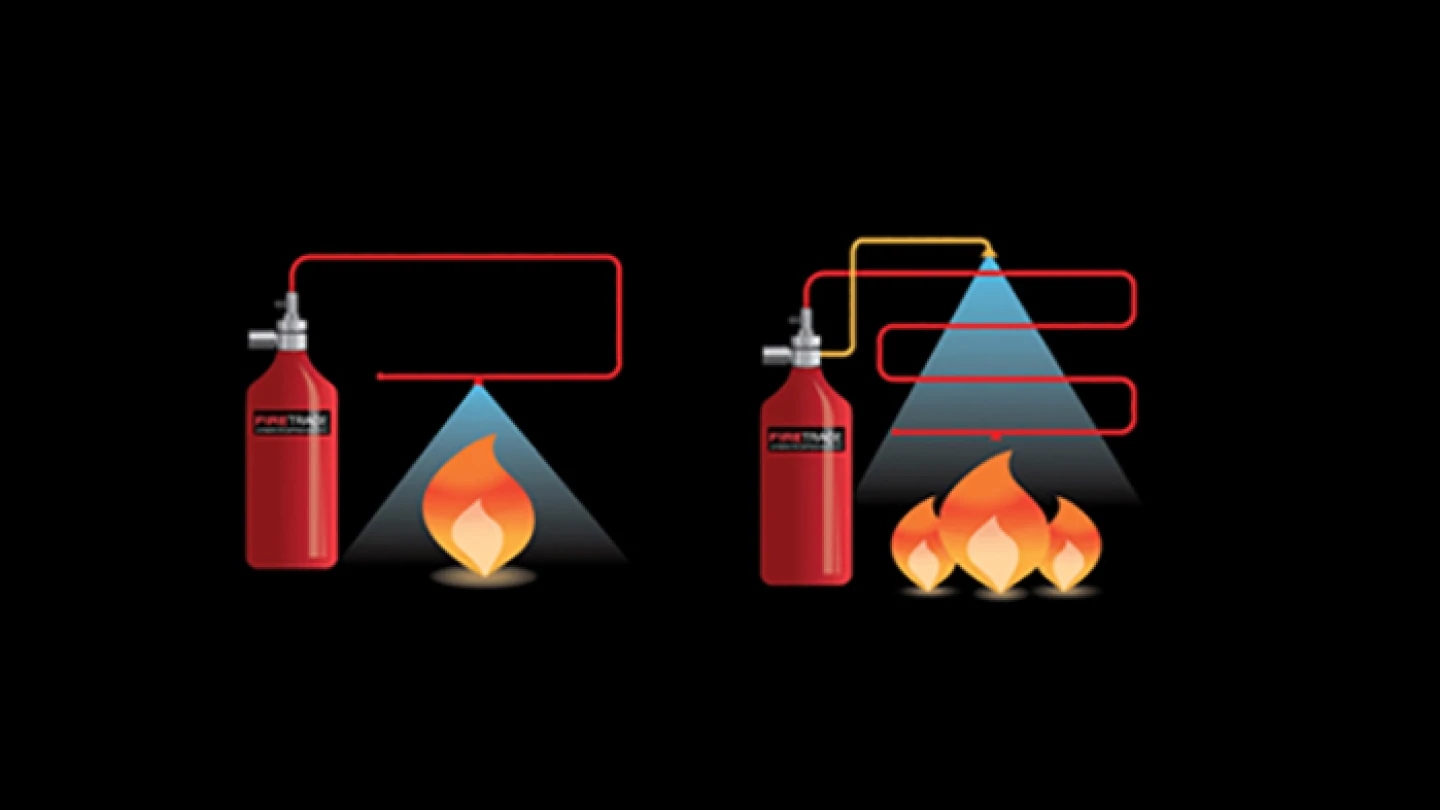

Total Flooding Systems

For room-wide protection, total flooding systems provide automated fire suppression. The clean agent type determines storage pressure, discharge characteristics, and system requirements.

Advantages

- Stored as pressurized liquids with nitrogen superpressurization (360 psi for HFC-227ea, 290 psi for Novec 1230).

- MEC: HFC-227ea (6.7%), Novec 1230 (4.2%) → Novec 1230 requires less agent volume.

- NFPA 2001: Must discharge within 10 seconds to prevent fire spread.

- Minimal Downtime – Fully evaporates, no cleanup required.

- Safe for Occupied Spaces – Low toxicity, ideal for data centers and control rooms.

- HFC-227ea has high GWP, making Novec 1230 a more environmentally friendly choice.

Inert Gas-Based Systems (IG-541, IG-55, IG-100)

Unlike halocarbons, inert gases (nitrogen, argon, and carbon dioxide) are stored as high-pressure gases (2,900-4,350 psi) and suppress fire by reducing oxygen levels from 20.9% to 12-15%.

Advantages

No Chemical Breakdown – No toxic byproducts, making it environmentally friendly.

Safe for Human Occupancy – Oxygen remains above 12%.

Requires Large Storage Space due to high-pressure cylinder storage.

Longer Discharge Time (Up to 60s) compared to halocarbons.

CO₂ Fire Suppression

CO₂ is NOT classified as a Clean Agent under NFPA 2001 but is still used for industrial applications. Stored as a liquid at 850 psi (58 bar), CO₂ suppresses fires by displacing oxygen, but it is lethal above 9% concentration.

Advantages

Effective for Class B & C Fires (flammable liquids and electrical).

Unsafe for Occupied Spaces – NFPA 12 requires pre-discharge alarms and safety measures.

Specialty Systems

Water Mist + Clean Agent, NFPA 750

- Combines water mist with clean agent for high-energy fire suppression.

- Ideal for turbines and industrial enclosures.

Aerosol Fire Suppression (UL 2775)

Compact storage for enclosed compartments.

Leaves residue, unlike gas-based clean agents.

| System Type | Agent Type | Storage Pressure | Applications |

| Portable Extinguishers | HFC-227ea, Novec 1230 | 290-360 psi | Small fires in server rooms, vehicles |

| Total Flooding – Halocarbon | HFC-227ea, Novec 1230 | 290-360 psi | Data centers, telecom facilities |

| Total Flooding – Inert Gas | IG-541, IG-55, IG-100 | 2,900-4,350 psi | Archives, museums, high-value storage |

| CO₂ Systems | Carbon Dioxide | 850 psi | Industrial hazards (non-occupied areas) |

| Hybrid Systems | Water Mist + Clean Agent | Variable | Turbines, power plants |

| Aerosol | Solid Compound | Canister-based | Engine compartments, electrical enclosures |

Over Traditional Fire Suppression Methods

Traditional fire suppression methods, such as fire sprinkler systems, dry chemical extinguishers, and CO₂ systems, often cause secondary damage or pose risks in sensitive environments. Clean agent fire suppression provides a fast, non-conductive, residue-free solution that ensures fire safety without compromising assets or human safety.

Unlike fire sprinkler systems, which release thousands of gallons of water and risk electrical damage, clean agents discharge within ≤10 seconds (NFPA 2001) and leave no residue, making them ideal for server rooms, control centers, and telecom facilities. Compared to dry chemical extinguishers, which leave corrosive byproducts requiring cleanup, clean agents fully evaporate, allowing for immediate resumption of operations in medical labs and semiconductor manufacturing. CO₂ systems, though effective, displace oxygen to dangerous levels (>9%), requiring evacuation before activation, while inert gas and halocarbon-based clean agents suppress fires without endangering occupants. Furthermore, modern clean agents like Novec 1230 and inert gases (IG-541, IG-55, IG-100) are environmentally friendly, with zero ozone depletion potential (ODP) and low global warming potential (GWP), unlike older suppression methods that contribute to chemical waste or excessive water use.

| Comparison | Clean Agent Systems | Fire Sprinkler Systems | Dry Chemical Extinguishers | CO₂ Systems |

| Water Damage | None | Significant | None | None |

| Residue Cleanup | None | None | Requires cleanup | None |

| Safe for Electronics | Yes | No | No | Yes |

| Human Safety | Safe | Safe | Safe | Requires Evacuation |

| Activation Speed | ≤10 sec | Slower | Manual operation | Fast, but hazardous |

| Environmental Impact | Low (Novec 1230, Inert Gases) | Water waste | Chemical residue | CO₂ emissions |

Choosing the right fire suppression system is a highly technical process, requiring expertise in fire risk assessment, system integration, and compliance with NFPA and ISO standards. With Flarenix’s team of experts, we will help you design and implement the optimal fire protection system, ensuring safety, efficiency, and compliance with industry regulations.