The demand for fixed fire protection systems is rising steadily across U.S. commercial and industrial facilities. According to NFPA and UL-listed system data, the market surpassed $4.5 billion in 2023, with annual growth projected at 6–8% through 2030 due to evolving fire codes and growing fire protection demands.

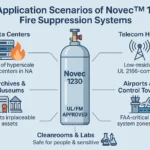

Among installed systems, clean agent systems make up approximately 32% of the market. These are widely deployed in data centers, telecom environments, and healthcare facilities due to their non-conductive and residue-free characteristics, which protect sensitive electronics and maintain post-discharge cleanliness. In contrast, dry chemical systems account for around 21%, and are typically selected for high-risk locations such as commercial kitchens, automotive paint booths, and fuel handling zones, where fast flame knockdown and agent density are critical to effective suppression.

While suppression agents and detection methods often receive the spotlight, the fire suppression systems valve is the mechanical heart of overall system performance. Whether controlling FM-200, CO₂, nitrogen, or dry powder, the fire suppression valve governs discharge timing, agent flow, and activation reliability.

Importantly, valve requirements vary across system types. A valve suited for high-pressure CO₂ may not meet the pressure ratings or actuation standards required for a nitrogen-based system. Material compatibility, sealing integrity, and installation conditions all play a role in proper function within your fire protection system.

Improper fire suppression valve selection can delay discharge or lead to system failure—outcomes with real consequences in high-risk facilities.

Common Valve Types in Fire Suppression Systems

In fire suppression systems, valves serve as the critical mechanical interface between agent storage and discharge. Especially in gaseous and dry chemical systems, the valve must reliably respond to control signals, regulate pressure, and ensure complete agent release within seconds—all while operating under high pressure and strict safety tolerances.

Used in Gaseous and Dry Chemical Systems

Solenoid-actuated valves – Frequently used in FM-200, Novec 1230, and inert gas systems, these electrically operated fire suppression valves allow precise, rapid agent release upon receiving a signal from the control panel. They support synchronized discharge across multiple zones and are widely used in UL 2166-compliant systems.

Pneumatically actuated valves – Standard in CO₂ systems and select hybrid systems, these valves open in response to pilot gas pressure from a master cylinder or dedicated activation line. They are ideal for power-independent reliability and consistent discharge timing.

Pressure-operated discharge valves – These valves are integral to modular cylinder designs. Actuation typically occurs when a puncture pin or release mechanism is triggered, utilizing the internal storage pressure of the agent to open the valve.

Selector valves – Deployed in multi-zone suppression systems, selector valves receive activation signals after the main discharge valve is opened. They redirect flow to the appropriate hazard zone, enabling efficient protection and conservation of agent inventory.

Check valves and discharge delay valves – Often required in CO₂ systems, these components prevent reverse flow and enable a delay before discharge to allow for personnel evacuation alarms, as mandated by NFPA 12.

Used in Water-Based Fire Protection

Although this article focuses on gaseous systems, it is important to acknowledge the role of butterfly valves, gate valves, and deluge valves in water-based fire protection systems. These valves provide manual control, isolation, or full-system flooding functions and are typically governed by NFPA 13 or NFPA 15.

Smart Fire Suppression Valves

An emerging trend in high-risk environments is the use of electronically monitored suppression valves. These advanced assemblies—offered by manufacturers such as Siemens, Rotarex, and Tyco—feature integrated pressure sensors, actuator position feedback, and programmable self-test functions. Many comply with UL 864 and can interface with fire alarm control panels for real-time diagnostics and remote supervision. In cleanrooms, data centers, and mission-critical facilities, these “smart valves” enhance safety transparency, reduce maintenance risks, and support predictive servicing.

Compatibility and Functional Differentiation

Valves are never one-size-fits-all in fire suppression design. The performance requirements for a fire suppression systems valve vary dramatically depending on the system’s extinguishing agent, cylinder pressure, discharge method, and zone architecture. Failure to match valve type to system behavior may result in agent leakage, delayed actuation, or even cylinder lockout—each with potentially catastrophic consequences.

For example, high-pressure CO₂ systems (typically 850–1,000 psi) require container valves and pressure relief assemblies engineered to withstand extreme thermal expansion and back-pressure surge during discharge. Since CO₂ is both dense and stored under high pressure, valve internals must maintain sealing integrity and precise blow-off thresholds. This level of mechanical durability is not transferable to other systems.

By contrast, systems using clean agents like FM-200 (HFC-227ea) or IG541 (a nitrogen/argon/CO₂ mix) operate at lower pressures but require highly coordinated directional control. In these cases, properly configured selector valves, check valves, and delay mechanisms are critical. Because inert gases are discharged in large volumes, the valve logic must prioritize distribution control over pressure ratings—a shift in design priorities not always obvious without engineering context.

In field applications, engineers often rely on multiple valve functions layered together—release, isolation, feedback—to meet NFPA 2001 or NFPA 12 compliance. Integration across fire protection systems requires terminological clarity and function-based thinking. What one manufacturer calls a pilot valve, another may label a driver valve or actuator assembly. Similarly, a pressure control valve in one system may resemble a pressure-regulating valve in another.

Regardless of naming differences, the engineer’s objective remains unchanged: to ensure timely agent discharge to maintain effective fire protection in each designated zone—with no delay, no leakage, and no uncertainty.

Standards for Fire Suppression Valves

In the United States, fire suppression systems valves are subject to stringent compliance requirements to ensure safe, reliable operation under real-world emergency conditions. These standards do more than establish mechanical tolerances—they directly govern valve actuation behavior, pressure ratings compliance, agent containment, and multi-zone coordination.

The most widely referenced standards include:

NFPA 12 (Carbon Dioxide Systems) – Specifies system performance parameters including pre-discharge alarms, time delays, and pressure relief. For valves, this means meeting strict criteria for pressure ratings compliance, container discharge timing, venting response, and fail-safe actuation to avoid CO₂ overconcentration in occupied spaces.

NFPA 2001 (Clean Agent Systems) – Defines safety, compatibility, and actuation logic for clean agents like FM-200 and Novec 1230. Valves used in these systems must support multi-zone directional flow, interlock logic, and check valve integrity to ensure agent discharge is contained to the intended enclosure.

UL 2166 / UL 2127 – UL 2166 applies to clean agent hardware, while UL 2127 governs high-pressure CO₂ system components. These standards test thermal shock resistance, mechanical vibration tolerance, and pressure cycling durability to verify long-term valve stability.

FM Approvals – Valves with FM approval undergo additional testing for industrial durability, including corrosion resistance, environmental exposure, and flow response under extreme conditions. In many government and military projects, FM-listed selector valves are required to meet specifications for critical operations zones.

Certified valves also streamline acceptance by Authorities Having Jurisdiction (AHJs) and facility insurers. In practice, the absence of a UL or FM listing can result in inspection rejections, delayed occupancy permits, or increased liability during post-incident investigations.

Whether specifying a pilot valve, selector valve, or fire suppression valve, certification is more than a checkbox—it’s an engineering safeguard. It ensures the selected valve maintains operational integrity within the fire protection system, meets code, and delivers as expected when it matters most.

The valve you select is not a minor component—it defines how your fire suppression system performs under pressure. Misapplied valve types, overlooked pressure ratings, or uncertified components can result in failed inspections or system malfunction when protection is most needed.

To avoid costly mistakes, Flarenix offers expert support in valve selection, compliance alignment, and system integration—ensuring your solution meets both technical demands and regulatory standards.

Connect with a Flarenix specialist today to protect your project from hidden engineering risks—before a small oversight becomes a system-wide failure.